Plastic fasteners, such as those used in the automotive industry, offer a unique set of advantages over traditional metal options. These fasteners are immune to corrosion, a common issue with metal fasteners, especially in environments with moisture or salt. Plastics like PVC, Isoplast, or PET are notable for their high strength-to-weight ratio, resistance to water absorption, and ability to withstand various chemicals and corrosive substances.

Another significant benefit of plastic fasteners is their resistance to UV radiation, which is particularly relevant for vehicles that are regularly exposed to sunlight. Specific plastics are designed to resist UV damage, ensuring longevity and durability. Additionally, the nonconductive nature of plastic makes these fasteners ideal for use in electrical and electronic applications within the automotive sector.

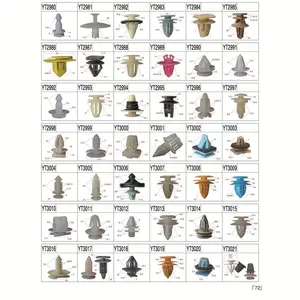

Cost-effectiveness is also a key feature of plastic fasteners. They are generally less expensive than metal fasteners, which can lead to considerable savings in mass production. Furthermore, the versatility of plastic allows for the creation of fasteners in complex shapes and any desired color without the need for secondary processes, unlike metal fasteners that require additional steps for shaping and finishing.

When choosing between plastic and metal fasteners for automotive applications, it's essential to consider the specific environmental, thermal, weight, chemical, and electrical requirements of the project. Plastic fasteners often emerge as the superior choice in many of these scenarios, providing a combination of performance, efficiency, and cost benefits.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4